(+375 163) 42-19-22

(+375 163) 42-26-96

MIM-600М MEAT MINCER

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

MIM-600M meat mincer is designed for grinding meat and fishand re-grinding patty mass at public catering facilities.

It is manufactured in climatic modification U under GOST 15150-69 for operation at temperatures from +1 to +40°С.

MIM-600М meat mincer is manufactured in accordance with the requirements of STB ISO 9001-2015 and has DECLARATION OF CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS, Certificate of Conformity to EU Directives - CE, Uniform Sanitary-Epidemiological and Hygienic Requirements and Eurasian Economic Union Conformity Certificate (Annex).

For convenience of operation of MIM-600M meat mincer, in case of auger stopping during processing of low-quality meat products, “Reverse” mode is provided (in comparison with MIM-600). By pressing “Reverse” button, you can return the product to filler neck and then send it for re-processing or remove it from meat mincer without disassembling the unit: blades - grinding plates - auger unit.

MIM-600M meat mincer is available with stainless steel facing. The lightweight supporting frame and the minimum number of parts make the machine lighter and more comfortable to use.

The worm gear used in MIM-600M meat mincer ensures smooth, quiet operation, and has increased torque at output shaft, that allows processing even very stringy meat.

Ventilated three-phase motor ensures continuous operation for many hours.

Basic technical parameters of meat mincer

Parameter description | Value |

|

Maximum performance (kg/h, minimum*) | 600 |

|

Performance during repeated mincing of patty mass (kg/h, minimum) | 200 |

|

Installed power (KW) | 2.2 |

|

Rated power consumption (KW) | 2.75 |

|

Auger rotation speed (rpm) | 185 |

|

Power supply: |

|

|

Overall dimensions (mm, maximum): |

| |

Weight (kg, maximum) | 45 |

* - Actual capacity of meat mincers depends on the speed of feeding of product pieces to the auger by the operator, the grade of meat being processed, and the quality of tool sharpening.

Machine composition

Designation | Description | Quantity per mincer | Note |

|

MIM-600М |

| |||

MIM-600М | Drive | 1 |

|

|

MIM-600М.14.000 | Mincer consisting of: housing, auger, clamping nut, double-edged blade (2 pcs.), scraper blade, grinding plate No.2, grinding plate No.3, stop ring | 1 |

|

|

| Clamp | 2 |

|

|

| Input device: - cabinet (protective housing) of type 3SD6 by SASSIN - Automatic circuit breaker of type ВА47-29, 3 poles, 400V, 50Hz, time-current characteristic “С” ТУ 2000 АИГЕ.641.235.003 6А Input device of specified parameters is an integral part of the machine. Violation of this requirement may result in machine malfunction. |

1 | optional |

|

| Cable Н05VV5-F 5G1 (or another similar) | 3.2 m | for mincer connection to circuit breaker |

|

Set of replaceable parts | ||||

MIM-600.01.002 | Stop ring | 1 |

|

|

| Grinding plate No.1 (3-mm holes) | 1 | supplied by separate order for additional payment | |

Composition and functionality of meat mincer

Meat mincer includes mincer and drive. The complete meat mincer consists of aluminum housing where the auger rotates, clamping nut, double- edged blades, set of grinding plates, stop ring and scraper blade.

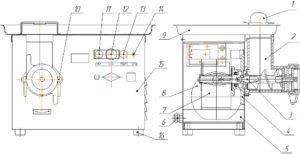

1- Pusher; 2- Meat mincer.

Drive: 3 - Driving shaft; 4 - Flange; 5 - Frame; 6 - Grounding clamp; 7 - Worm reducer; 8 - Electrical motor; 9 - Tray with protection element; 10- Clamp; 11- “Start” button; 12 – “Stop” button; 13 – “Reverse” button; 14 – “Power” indicator; 15 - Facing; 16 - Support.

Housing is secured with threaded clamps.

Fixed protection element is located above the feeding hole and prevents the possibility of contact of operator’s hands with the auger of the running machine.

Meat or fish should be deboned, cut into pieces weighing not more than 0.05 kg. Connective tissues and cords should be removed from the product being processed. Recommended temperature of the processed product should be +8 ± 2°С.

The processed product should be manually fed from the tray to meat mincer housing neck, and then pushed to the rotating auger. The product is moved by the auger and passes sequentially through the set of cutting tools.

To obtain mince of different fineness degree, the mincer is equipped with a set of grinding plates with holes of various sizes. Grinding plates should be inserted into mincer housing and kept from turning by a key.

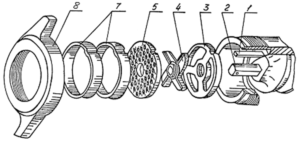

Coarse mincing set

1 – key; 2 – auger; 3 – scraper blade; 4 – double-edged blade; 5 – grinding plate with 9-mm holes; 7 – stop ring; 8 – clamping nut

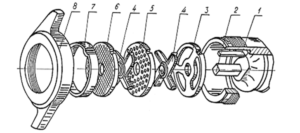

Fine mincing set

1 – key; 2 – auger; 3 – scraper blade; 4 – double-edged blade; 5 – grinding plate with 9-mm holes; 6 – grinding plate with 5-mm holes; 7 – stop ring; 8 – clamping nut

The most effective mincer operation is achieved when mounting a set of cutting tools for coarse mincing.

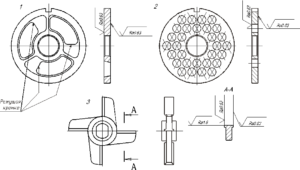

Grinding plate parameters

Grinding plate parameters | Plate No. | ||

1 (by order) | 2 | 3 | |

External diameter (mm) | 105 | 105 | 105 |

Hole diameter (mm) | 3 | 5 | 9 |

Number of holes | 276 | 132 | 54 |

Long-time idle operation of the mincer (with no product loading) is impermissible as dry friction results in damage to clamped blades and grinding plates.

Sharpening of blades and grinding plates

1 - Scraper blade; 2 – Grinding plate; 3 – Double-edged blade

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After machine unpacking, check delivery set in accordance with paragraph 1.3 of Operating Manual.

Mounting

All the works upon machine connection to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are obfed:

- Observance of all the requirements of the “Operation Manual”.

- Handing over (sending) a copy of properly drawn-up “Act of putting the machine into operation” to manufacturing company within 14 days from the day of putting the machine into operation.

- Sending a copy of properly drawn-up “Damage Claim” containing information on machine failure or malfunction of its parts.

In case of non-observance of any of the above-specified conditions, the manufacturing company disclaims all its warranty liabilities.

Note: the drawn-up “Act of putting the machine into operation” and “Damage Claim” shall be stamped by a consumer and by the company performing repair and maintenance.