(+375 163) 42-19-22

(+375 163) 42-26-96

MIM-300 AND MIM-600 MINCERS

MIM-300 and MIM-600 mincers are designed for meat and fish mincing, patty mince repeated mincing and sausages stuffing at public catering facilities.

The mincers are manufactured with stainless steel facing in “У3” modification (moderate climate; category of placement 3: enclosed rooms with natural ventilation) as per GOST 15150-69 for operation at temperatures from +1°С to +40°С.

MIM-300 and MIM-600 meat mincers are manufactured in accordance with the requirements of STB ISO 9001-2009 standard. They are approved in accordance with the DECLARATION OF CONFORMITY TO THE REQUIREMENTS OF TECHNICAL REGULATIONS, Declaration of compliance with unified sanitary, epidemiological and hygienic requirements, EU directive Conformity Certificate - CE and Eurasian Economic Union Conformity Certificate (Annex).

Basic technical specifications of the mincers

Parameter description | МIМ-300 | МIМ-600 |

Maximum capacity (kg/h, not less*) | 300 | 600 |

Capacity during repeated mincing of patty mass (kg/h, minimum) | 100 | 200 |

Rated power consumption (kW) | 1,90 | 2,71 |

Installed power (kW) | 1,5 | 2,2 |

Power supply: - current type - rated voltage (V) - current frequency (Hz) |

three-phase, alternating 380 50 | |

Auger rotation speed (rpm) | 250 | |

Overall dimensions (mm, maximum) - length - width - height |

680 400 460 |

765 400 540 |

Weight (kg, maximum) | 42 | 55 |

* - Actual capacity of meat mincer depends on the speed of feeding of product pieces to the auger by the operator, the grade of meat being processed, and the quality of tool sharpening.

Composition of the machines

Model designation | Description | Quantity per mincer (pcs.) | |

МIМ-300 | МIМ-600 | ||

МIМ-300 | Drive | 1 |

|

МIМ-600 | Drive |

| 1 |

МIМ-300.01.000 | The mincer consisting of: housing, auger, clamping nut, double-edged blade (2 pcs.), scraper blade, grinding plate No.2, grinding plate No.3, stop ring | 1 |

|

МIМ-600.01.000 | The mincer consisting of: housing, auger, clamping nut, double-edged blade (2 pcs.), scraper blade, grinding plate No.2, grinding plate No.3, stop ring |

| 1 |

| Clamp | 2 | 2 |

| Input device: automatic circuit breaker of type ВА 47-29, 3 poles, 50Hz, time-current characteristic “С”, ТУ 2000 АГИЕ.641.235.003, 4А 6A Parameter input device is an integral part of the machine. Non-fulfillment of this requirement may cause damage to the machine. |

1 Note: added by customer |

1 Note: added by customer |

| Cable H05VV5-F 5G1 (or other similar cable for mincer connection to automaic circuit breaker), | 3,2 м Note: added by customer | 3,2 м Note: added by customer |

МIМ-300.01.002 | Stop ring | 1 |

|

МIМ-600.01.002 | Stop ring |

| 1 |

| Grinding plate No.1 (Ø 3-mm holes) | 1 Note: supplied by separate order for additional payment |

|

| Решетка № 1 (отверстие Ø3 мм) |

| 1 Note: supplied by separate order for additional payment |

Set of accessories | |||

МIМ-300.00.020 | Extractor | 1 | 1 |

МIМ-300.00.021 | Attachment | 1 | |

МIМ-300.10.000 | Support | 1 | |

МIМ-300.28.000 | Pusher | 1 | |

МIМ-1.26.000 | Pusher | 1 | |

МIМ-600.00.021 | Attachment | 1 | |

МIМ-600.10.000 | Support | 1 | |

Set of package | |||

Package box | 1 | ||

Package box | 1 | ||

Documentation | |||

МIМ-300(600) РЭ | Operating manual (OM) | 1 | 1 |

МIМ-300 (600) Д1 | Quick user’s guide | 1 (included in OM) | 1 (included in OM) |

МIМ-300 (600) Д2 | Safety instructions for mincer usage | 1 (included in OM) | 1 (included in OM) |

Composition and functionality of the mincers

Each mincer consists of meat mincer itself and a drive. Meat mincer assembly consists of aluminum housing with rotary auger, clamping nut, double-edged blades, set of grinding plates, stop ring and scraper blade.

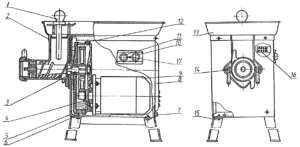

1 – pusher; 2 – mincer assembly

Drive: 3 – driving shaft; 4 – oil level inspection hole; 5 – front facing; 6 – drain plug; 7 – equipotential clamp; 8 – rear facing; 9 – electrical motor; 10 – “Start” button; 11 – “Stop” button; 12 – plug; 13 – tray with protection element; 14 – clamp; 15 – support; 16 – terminal block; 17 – indicator

Housing is fastened with threaded clamps.

Fixed protection element is located above the feeding hole. It prevents operator’s hands from the possibility of contact with mincer auger.

Meat or fish should be deboned, cut into pieces weighing not more than 0.1 kg. Recommended temperature of the processed product should be +8 ± 2°С. Connective tissues and cords should be removed from the product being processed.

The processed product should be manually fed from the tray to mincer housing neck and then pushed to rotating auger. The product is drawn by the auger and passed sequentially through the set of cutting tools.

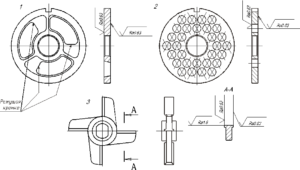

To obtain mince of different fineness degree, the mincer is equipped with a set of grinding plates with holes of various sizes. Grinding plates should be inserted into mincer housing and kept from turning by a key.

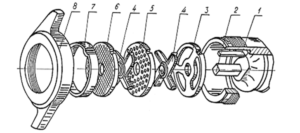

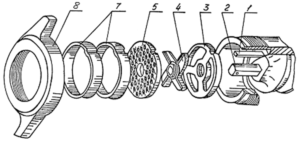

Fine mincing set

1 – key; 2 – auger; 3 – scraper blade; 4 – double-edged blade; 5 – grinding plate with 9-mm holes; 6 – grinding plate with 5-mm holes; 7 – stop ring; 8 – clamping nut

Coarse mincing set

1 – key; 2 – auger; 3 – scraper blade; 4 – double-edged blade; 5 – grinding plate with 9-mm holes; 7 – stop ring; 8 – clamping nut

The most effective mincer operation is achieved when mounting a set of cutting tools for coarse mincing.

Grinding plate parameters

Grinding plate parameter description | Grinding plate number | |||||

МIМ-300 | МIМ-600 | |||||

1 (by order) | 2 | 3 | 1 (by order) | 2 | 3 | |

External diameter (mm) | 82 | 82 | 82 | 105 | 105 | 105 |

Hole diameter (mm) | 3 | 5 | 9 | 3 | 5 | 9 |

Number of holes (pcs.) | 217 | 90 | 30 | 276 | 132 | 54 |

Long-time idle operation of the mincer (with no product loading) is impermissible as dry friction results in damage to clamped blades and grinding plates.

Sharpening of blades and grinding plates

1 - scraper blade; 2 - grinding plate; 3 - double-edged blade

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After unpacking, check the completeness of delivery in accordance with paragraph 1.3 of the Operating Manual.

Mounting

All the works upon connecting the machine to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for the Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of the importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are observed:

- Observance of all the requirements of “Operating Manual” regarding the machine.

- Putting into operation and monthly maintenance is performed by a specialized company (under consumer agreement) in accordance with the list of companies or by other repair companies under written permission of the manufacturer.

- Handing over (sending) the copy of signed “Act of machine commissioning” (Annex И) to manufacturing company within 14 days from the day of putting the machine into operation.

- Sending the “Damage claim” (Annex К), containing the information on machine malfunction, failure of its parts or utilities to manufacturing company.

In case of non-observance of any of the above-specified conditions, the manufacturing company will disclaim all its warranty liabilities.

Note: the drawn-up “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by repair/maintenance company.