(+375 163) 42-19-22

(+375 163) 42-26-96

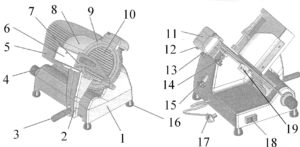

LR-300 SLICER

The company is included in the Registry of bona fide partners of BelCCI.

LR-300 slicer is designed for precise slicing of any food products (from sausages to hard cheeses) without waste. It can be used in public catering and trade facilities, in shops, canteens, cafes, restaurants, etc.

It is manufactured in climatic modification UHL4 (moderate climate) under GOST 15150. Operating air temperature range: from +1 to +35°С.

LR-300 slicer is manufactured in accordance with the requirements of STB ISO 9001-2015 and has Eurasian Economic Union Conformity Declaration (Annex), DECLARATION OF CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS.

Basic technical parameters of the slicer

Parameter description | Value |

Type | semi-automatic, with manual product feed |

Disc cutter diameter (mm) | 300 |

Slicing thickness (mm) | 0...18 |

Installed motor power (KW, maximum) | 0.16 |

Rated power consumption (KW) | 0.27 |

Motor speed (rpm) | 1400 |

Disc cutter speed (rpm) | 470 |

Overall dimensions (mm, maximum): |

|

Power supply: |

|

Weight (kg, maximum) | 28.5 |

Machine composition

Product composition | Quantity per modification |

LR-300 | |

Slicer (drive assembly) | 1 |

Carriage assembly with carriage support and clamping device | 1 |

Carriage handle | 1 |

Set of package | |

Package box | 1 |

Documentation | |

Operation manual LR-300 (OM) | 1 |

Composition and functionality of the slicer

Slicer consists of a housing (with electric motor), sharpening device, carriage, clamping device, cutter, protective screens.

1- housing; 2 - carriage support; 3 - carriage handle; 4 - thickness adjustment handle; 5 – limiter; 6 – carriage; 7 - clamping device; 8 - carriage screen (not applied in this modification); 9 - cutter; 10 - cutter screen; 11 - sharpening device; 12 - sharpening device handle; 13 - sharpening device fixing screw; 14 - stop screw; 15 - cutter screen fixing screw; 16 – legs; 17 - cord and plug; 18 - motor START-STOP switch; 19 - cutoff.

Food products should be placed on the tray and secured with clamping device. The slicer provides fast and precise cutting into slices of a selected thickness. It is equipped with built-in cutter sharpener. To provide safe use of the slicer, disc cutter is placed in a protective casing. Design of the machine allows easy and smooth movement of feeding tray. Cast base is applied. The disc cutter is made of stainless steel. Power-saving motor with cooling fan and waterproof switch ensure compliance with safety standards.

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After machine unpacking, check delivery set in accordance with paragraph 1.3 of Operating Manual.

Mounting

All the works upon machine connection to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are obfed:

- Observance of all the requirements of the “Operation Manual” regarding the machine.

- Mounting and putting into operation is performed by specialists of servicing company or by specialists of another company under written permission of the manufacturer.

- Handing over (sending) a copy of properly drawn-up “Act of putting the machine into operation” to manufacturing company within 10 days from the day of putting the machine into operation in order to provide warranty registration.

- Performing monthly maintenance under the “Operation Manual”.

- Handing over (sending) a copy of properly drawn-up “Damage Claim”.

Monthly maintenance operations in accordance with the requirements of the “Operation Manual” are NOT warranty maintenance and should be performed at consumer’s expense by specialized companies under a preliminary agreement.

In case of violation of at least one of the aforementioned conditions, the manufacturer disclaims their warranty liabilities.

Note: the drawn-up “Act of putting the machine into operation” and “Damage Claim” shall be stamped by a consumer and by the company putting the machine into operation or performing its repair and maintenance.