(+375 163) 42-19-22

(+375 163) 42-26-96

MPR-350M PULPING AND CUTTING MACHINES

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

MPR-350M pulping and cutting machines are designed for pulping boiled food products (potatoes, beets, carrots, thin porridge, peas, beans, apples, curd cheese, etc.), cutting raw and boiled food products (potatoes, beets, carrots, onions, turnips, cucumbers, tomatoes, etc.) into particles of various geometric shapes, fine grinding of potatoes, carrots, and cabbage.

They are designed for use in catering and small vegetable processing companies.

The machines are manufactured for operation at temperatures from +1 to +35°С in climatic modification UHL4 (moderate climate) under GOST 15150-69.

Pulping and cutting machines of MPR-350M type are manufactured in accordance with the requirements of STB ISO 9001-2015 standard and have DECLARATION OF CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS, Uniform Sanitary-Epidemiological and Hygienic Requirements, Certificate of Conformity to EU Directives - CE and EAC Certificate of Conformity (Annex).

Available in three modifications:

- MPR-350М - for cutting raw and boiled food products and for pulping boiled food products.

- MPR-350М-01 - for pulping boiled food products.

- MPR-350М-02 - for cutting raw and boiled food products.

Basic technical parameters of the machines

| ||||||||||||||||||||||||||||||||||||||||

Performance of machines depending on the type and size of slices and type of pulping

Types of processing, types and sizes of slicing | Performance (kg/h, minimum) |

|

Slicing | ||

of potatoes in slices with a thickness of 10 mm | 350 |

|

in slices with a thickness of 2 mm | 100 |

|

in sticks with a section of 4х3 mm | 110 |

|

in blocks with a section of 5х10 mm | 200 |

|

in cubes (10х10х10 mm) | 250 |

|

in blocks with a section of 10х10 mm | 250 |

|

of beets in slices with a thickness of 2 mm | 100 |

|

in sticks with a section of 4х3 mm | 110 |

|

of carrots in slices with a thickness of 2 mm | 100 |

|

in sticks with a section of 1.3х3.5 mm | 100 |

|

in sticks with a section of 4х3 mm | 110 |

|

in sticks with a section of 2х2 mm | 150 |

|

of turnips in slices with a thickness of 2 mm | 100 |

|

in sticks with a section of 4х3 mm | 110 |

|

fresh and pickled cucumbers in sticks with a section of 4х3 mm | 110 |

|

of bulb onion in rings (half-rings) with a thickness of 2 mm | 100 |

|

Fine grinding | ||

potato | 120 |

|

carrot | 60 |

|

Grinding | ||

of cabbage (thickness - 2 mm) | 220 |

|

Pulping using a pulping disc with 4-mm holes | ||

boiled potatoes | 600 |

|

boiled peas, beans | 300 |

|

boiled carrots, beets (after pulping using pulping disc) | 100 |

|

thin porridge | 300 |

|

curds | 300 |

|

baked apples | 400 |

|

pumpkin | 400 |

|

Pulping using a pulping disc with 1.5-mm holes | ||

thin porridge | 150 |

|

Composition and equipment of machines with replaceable tools

Product composition | Quantity (pcs.) | ||

MPR-350М | MPR-350М-01 | MPR-350М-02 | |

Drive MPR-350М.01.00.00 | 1 | 1 |

|

Drive MPR-350М.01.00.00-02 |

|

| 1 |

Pulping device MPR-350М.02.00.00 with rotor MPR-350М.08.00.00 and pulping disc with 4-mm holes MPR-350М.00.00.04 | 1 | 1 |

|

Slicing device MPR-350М.03.00.00 with combined blade 5х10 mm MPR-350М.14.00.00 | 1 |

| 1 |

Set of replaceable tools | |||

2-mm disc cutter MPR-350М.10.00.00 | 1 |

| 1 |

pulping disc MPR-350М.11.00.00 | 1 |

| 1 |

fine grinding disc MPR-350М.12.00.00 | 1 |

| 1 |

grinding disc 4х3 mm MPR-350М.13.00.00 | 1 |

| 1 |

disc cutter 10 mm MPO-1.04.06.00 | 1 |

| 1 |

cutting plate 10х10 mm MPO-1.04.03.00 | 1 |

| 1 |

blade for cutting in sticks 2х2 mm MPO-1.04.16.00 | 1 |

| 1 |

pulping disc d1.5 mm MPR-350М.00.00.05 | 1 | 1 |

|

cutting plate 10 mm MPR-350U.07.00.00 | 1 |

|

|

slicing blade 10 mm MPR-350U.08.00.00 | 1 |

|

|

Set of accessories | |||

brush MPR-350М.00.00.10 | 1 | - | 1 |

paddle MEB-1.00.50 | 1 | 1 | - |

pusher MPR-350М.03.00.04 | 1 | - | 1 |

pusher MPR-350М.03.00.04-01 | 1 | - | 1 |

Set of mounting parts | |||

3SD6 exposed installation cabinet with “zero bus” and ground bus for three-pole circuit breaker Automatic circuit breaker of type ВА47-29, 3 poles, 415V, 50Hz, time-current characteristic “С”, ТУ2000 АГИЕ.641.235.003 2.5 А 1.6 А Input device of specified parameters is an integral part of the machine. Violation of this requirement may result in machine malfunction. | 1 Note: optional

1 Note: optional | 1 Note: optional

1 Note: optional |

1 Note: optional

1 Note: optional |

Cable H05VV5-F 5G1 (or another similar) for machine connection to automaic circuit breaker), overall length (m) | 3.2 Note: optional | 3.2 Note: optional | 3.2 Note: optional |

Set of package | |||

package box | 1 | 1 | 1 |

accessory kit box | 1 |

| 1 |

Documentation | |||

Operation manual MPR-350М OM | 1 | 1 | 1 |

Quick user’s guide for machines of type MPR-350М D1 | 1 (included in OM) | 1 (included in OM) | 1 (included in OM) |

Safety instructions for machines of type MPR-350М D2 | 1 (included in OM) | 1 (included in OM) | 1 (included in OM) |

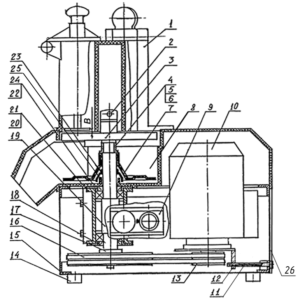

Composition and functionality of pulping and slicing machines

The machines consist of drive, shaft and processing chamber. The drive includes electric motor, pulleys and V-belt.

1 - Slicing device; 2 - Special screw; 3 - Replaceable processing tools; 4 - Bushing; 5 - Adjusting nut; 6 – Lock nut; 7 - Discharger; 8 - Processing chamber of tray; 9 - Panel; 10 - Electric motor; 11 - Tensioning bolt; 12 - Motor base; 13.17 - Pulleys; 14 - Support; 15 - Frame; 16 - V-belt (Z (0) -800 GOST 1284.1-89); 18.24 - Lids; 19 - Shaft; 20 - Bearings (206 GOST 8338-75); 21 - Cup; 22 - Cuff; 23 - Reflector; 25 - Nut; 26 - Pad; B - Working clearance

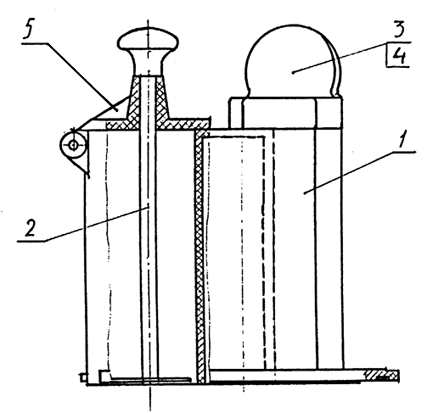

To grind raw and boiled food products, one of the replaceable processing tools should be mounted on the shaft. Slicing device is mounted on processing chamber. The processed product is fed into one of the hatches of cutting device and is pushed into cutting zone with pushers.

1 - Housing; 2 - Sickle-shaped pusher; 3.4 - Cylindrical pushers; 5 - Bracket

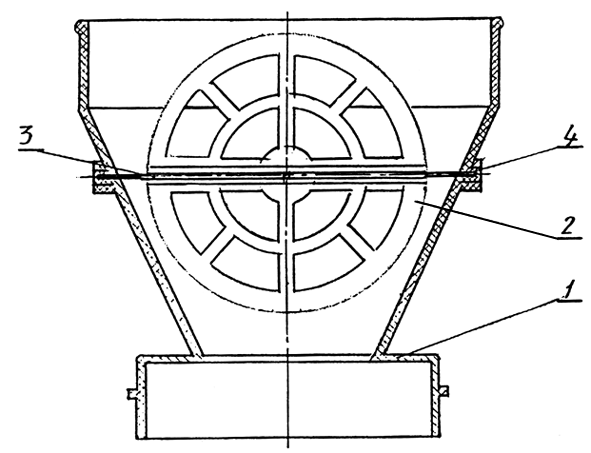

For pulping boiled food products, pulping disc should be mounted on the shaft before blade rotor mounting. Pulping device is installed on processing chamber.

1 - Housing; 2 - Fuse; 3 - Axis; 4 - Bushing

Wash vegetables and potatoes, peel and remove “eyeholes”. Peel cabbage head from dirty leaves, cut out stalk, and cut it into pieces.

Potatoes should be fed for pulping peeled, without “eyeholes”, boiled, without water, according to the recipe of catering facility. The temperature of pulped potatoes should be from +85 to +90°С.

Cereals and beans are fed boiled in the form of thin porridge. Curd cheese is pulped without pre-treatment. Apples are fed for mashing washed and with no seeds, baked or boiled. Carrots and beets are fed boiled, peeled and chopped using grating disc.

Pulped vegetables and curd cheese should be homogeneous, without lumps. Pulped potatoes should be homogeneous, not viscous, without lumps. Potatoes should not be cooled below +80°С.

When pulping thin porridge, grain shell should settle on pulping disc. In order to avoid getting peel pulp into the pulped mass, the disc should be regularly cleaned.

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After machine unpacking, check delivery set in accordance with paragraph 1.3 of Operating Manual.

Mounting

The place of machine installation should ensure safety and ease of operation and maintenance. It should comply with sanitary standards, fire safety requirements, labor safety instructions and mounting guide.

All the works upon machine connection to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, “Rules for Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are obfed:

- Observance of all the requirements of the “Operation Manual” regarding the machine.

- Mounting and putting into operation is performed by specialists of servicing company or by specialists of another company under written permission of the manufacturer.

- Handing over (sending) a copy of properly drawn-up “Act of putting the machine into operation” to manufacturing company within 10 days from the day of putting the machine into operation in order to provide warranty registration.

- Performing monthly maintenance under the “Operation Manual”.

- Handing over (sending) a copy of properly drawn-up “Damage Claim”.

Monthly maintenance operations in accordance with the requirements of the “Operation Manual” are NOT warranty maintenance and should be performed at consumer’s expense by specialized companies under a preliminary agreement.

In case of violation of at least one of the aforementioned conditions, the manufacturer disclaims their warranty liabilities.

Note: the drawn-up “Act of putting the machine into operation” and “Damage Claim” shall be stamped by a consumer and by the company putting the machine into operation or performing its repair and maintenance.