(+375 163) 42-19-22

(+375 163) 42-26-96

BONE SAW PLM-240

In 2018, our company has mastered manufacturing of brand-new equipment, taking into account the modern requirements for quality, engineering and production capacities!

PLM-240 band saw for meat products is designed for fast cutting of chilled or frozen meat, bone-in meat or bones into portions of various size.

It is manufactured in УХЛ 4 (moderate and cold climate, adjustable environment) modification in accordance with GOST 15150-69.

The saw is notable for reliability, safety and compliance with Technical Regulations of the Customs Union, ease of maintenance and durability.

PLM-240 saw is manufactured in accordance with the requirements of the standard STB ISO 9001-2015 and has the Declaration of Conformity of the Eurasian Economic Union (see Annex).

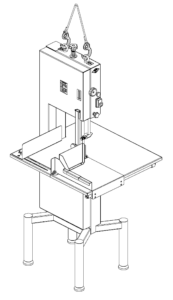

High-quality stainless steel housing is manufactured in floor-mounted modification on four adjustable supports providing machine installation on uneven surface.

Maximum cutting height is 300 mm, cutting width is 280 mm. The saw is equipped with a device for cutting the last portion of the product.

Saw table is equipped with additional movable folding table, where chilled meat can be cut.

Linear scale with 5-mm divisions is applied at the table for convenient cutting of pieces of the required thickness.

Basic technical specifications of the saw

Parameter name | PLM-240 |

Technical performance (kg/h*) | 500 |

Power consumption (kW) | 1,91 |

Installed power (kW) | 1,5 |

Thickness, width and length of saw band (mm) | 0,6х20х2490 |

Cutting height (maximum, mm) | 300 |

Power supply: - current type - rated voltage (V) - current frequency (Hz) | three-phase alternating 380 50 |

Overall dimensions (mm, maximum) - length - width - height |

795 730 1750 |

Weight (kg, maximum) | 115 |

* - Technical performance of the saw depends on the speed of product feeding by the operator, the dimensions, the density and the grade of pieces of product being processed.

Machine composition

Model designation | Description | Quantity per saw |

PLM-240 | Saw | 1 |

Cable H05VV5-F-4G2,5 with portable plug CCИ-015 16А 240/380 В 3Р+РЕ+N, IP44 | 1 | |

Set of spare parts | ||

Saw band | 1 | |

Set of accessories | ||

Device for cutting the last portion of the product | 1 | |

Wrench 7811-0109 С 1х9 GOST 2841-80 | 1 | |

Eye-bolt М12 GOST 4751-73 | 2 | |

Set of packaging | ||

Package box | 1 | |

Documentation | ||

PLM OM | Operating manual | 1 |

PLM Д1 | Quick user’s guide | 1 (included in OM) |

PLM Д2 | Safety instructions for saw usage | 1 (included in OM) |

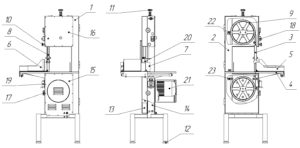

Saw composition and functionality

The saw is actuated by electric motor 21 where pulleys 9 are fixed. The pulleys drive band 20. The band is tensioned by rotating nut 11. The product is cut by passing it through band 20. Cutting width can be adjusted using limiter 7. For cutting chilled products, use a movable table 5. For cutting the last portion of the product, use the device for cutting the last portion of the product 6. For the convenience of saw operation, optimally set protective plate 8 by height (depending on product cutting height) and secure it with screw 10. Do not use the saw with no product pusher 3 when movable table is not used.

Figure

1 - Housing; 2 - Door; 3 - Pusher; 4 - Table; 5 - Movable table; 6 - Device for cutting the last portion of the product; 7 - Limiter; 8 - Protective plate; 9 - Pulleys; 10 - Protective plate screw; 11 - Nut; 12 - Support; 13 - Tray; 14 - Casing; 15 - Electric motor shield; 16 - Cover; 17 - Clamping cam; 18 – “Start-Stop” button; 19 - Protection device (automatic circuit breaker); 20 - Saw band; 21 - Electric motor; 22 - Saw band flying-off preventer; 23 - Brushes

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package by any type of covered vehicles in upright position, except for air, in accordance with applicable rules for transportation of goods fot this means of transportation.

After machine unpacking, check the completeness of delivery in accordance with paragraph 1.3 of the Operating Manual.

Perform saw handling after unpacking using lifting devices of appropriate capacity.

Mounting

The place of machine installation should ensure safety and ease of operation and maintenance, and should comply with sanitary standards, fire safety requirements, labor safety instructions and wiring diagrams. It should prevent the machine from sliding, tilting or overturn in any operation mode.

All the works upon connecting the machine to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for the Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of the importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are observed:

1. Observance of all the requirements of “Operating Manual” regarding the machine.

2. Putting into operation and monthly maintenance is performed by a specialized company (under consumer agreement) in accordance with the list of companies or by other repair companies under written permission of the manufacturer.

3. Handing over (sending) the copy of signed “Act of machine commissioning” (Annex И) to manufacturing company within 14 days from the day of putting the machine into operation.

4. Sending (handing over) the “Damage claim” (Annex К), containing the information on machine malfunction, failure of its parts or utilities.

In case of non-observance of any of the above-specified conditions, the manufacturing company disclaims all its warranty liabilities.

Note: the drawn-up “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by repair/maintenance company.