(+375 163) 42-19-22

(+375 163) 42-26-96

MOK-150U and MOK-300U ROOT CROP PEELERS

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

The peelers are designed for peeling potatoes and root crops (beets, carrots) at public catering and trade facilities. They are manufactured in a floor modification with stainless steel facing.

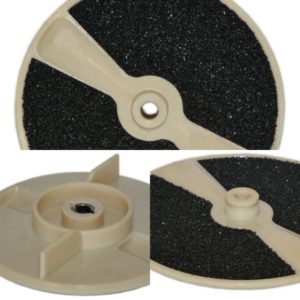

Since November 2016 MOK-150U and MOK-300U root crop peelers are manufactured with a new discharge door, a new locking mechanism and a new abrasive disc made of high-strength and low-wear material. It should be noted that the new abrasive disc does not require balancing.

- Люк

- Замок

They are manufactured in UHL4 (moderate climate) modification under GOST 15150-69 for operation at temperatures from +1 to +35°С.

MOK-150U and MOK-300U root crop peelers are manufactured in accordance with the requirements of STB ISO 9001-2015 and have DECLARATION OF CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS, Certificate of Conformity to EU Directives - CE, Uniform Sanitary-Epidemiological and Hygienic Requirements and Eurasian Economic Union Conformity Certificate (Annex).

MOK-150U and MOK-300U root crop peelers were created specifically for EU market in accordance with European requirements and have already proven themselves positively among European buyers.

Main differences of root crop peelers MOK-150U and MOK-300U from MOK-150М and MOK-300М potato peelers:

- Side drain tube (of stainless steel) allows installation of peel pulp collector (of stainless steel; included in delivery set) under it.

- Built-in time relay, that allows setting optimal peeling mode and saving power.

Basic technical parameters of the machines

Parameter description | Parameter value | |

MOK-300U | MOK-150U | |

Performance (kg/h, minimum*) | 300 | 150 |

Peeling efficiency (%, minimum*) | 90 | 90 |

Volume of simultaneously loaded product (potato) (kg, maximum*) | 10 | 7 |

Percentage of potato waste during peeling (maximum*) | 20 | 20 |

Nimber of discs (pcs.) | 2 | 2 |

Rated power consumption (KW, maximum) | 0.75 | 0.51 |

Installed power (KW) | 0.55 | 0.37 |

Overall dimensions (mm, maximum): length width height |

580 480 850 |

580 480 800 |

Power supply: current type rated voltage (V) current frequency (Hz) |

three-phase alternating 380 50 | |

Cold water flow (l/kg, maximum) | 1.0 | 1.0 |

Total processing cycle duration (including filling and discharge) (min., maximum) | 2.0 | 2.0 |

Weight (kg, maximum) | 35 |

34

|

* - Capacity is checked at 90% of completely peeled potatoes. A tuber is considered peeled when peel remains in the recesses and in no more than three unpeeled areas (with maximum size from 1 to 3 mm) on the remaining surface (values for root crops (beets, carrots) are not specified).

Machine composition

Designation | Description | Quantity per one machine | |

MOK-300U | MOK-150U | ||

MOK-300U | Root crop peeler consisting of: grid, abrasive disc, peel pulp collector | 1 |

|

MOK-150U | 1 | ||

Set of spare parts | |||

MOK-300U-01.30.000 | Abrasive disc | 1 | 1 |

Mounting parts | |||

| Worm drive clamp 3/4''- 11/8'' | 1 | 1 |

| Input device with automatic circuit breaker of type ВА 47-29 400 V, ~50 Hz, 3 poles, time-current characteristic “C”, ТУ 2000 АГИЕ.641.235.003 1.6 А 2.0 А

Automatic circuit breaker of specified type is an integral part of the machine. Non-fulfillment of this requirement may cause damage to the machine |

1 Note: optional | 1 Note: optional |

| 3SD6 exposed installation cabinet with “zero bus” and ground bus | 1 Note: optional | 1 Note: optional |

| Cable H05VV5-F5G1 (or another similar) | overall length 3.6 m Note: for machine connection to automaic circuit breaker | overall length 3.6 m Note: for machine connection to automaic circuit breaker |

| Expansion anchor Screw with hexagonal head 10х90 Washer А.10.21.08Х18Н10 GOST 11371-78 | 4 4 4 | 4 4 4 |

Set of package | |||

| Package box | 1 | 1 |

Documentation | |||

MOK-300U, MOK-150U OM | Operation manual | 1 | 1 |

MOK-300U, MOK-150U D1 | Quick user’s guide for root crop peeler | 1 (included in OM) | 1 (included in OM) |

MOK-300U, MOK-150U D2 | Safety instructions for operation of root crop peelers | 1 (included in OM) | 1 (included in OM) |

Composition and functionality of root crop peeler

The machine consists of a housing with grid, feeding lid, motor and peel pulp collector.

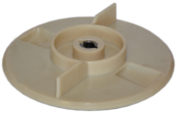

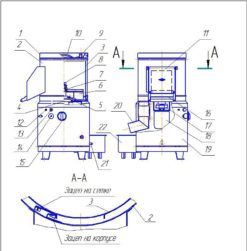

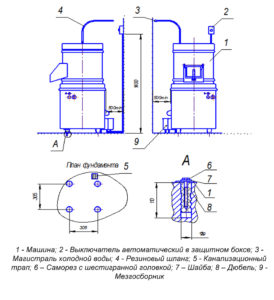

1- Funnel, 2-Housing, 3- Grid, 4- Cup with bearings; 5- Lid with cuffs 2.2-30x52-1 G0ST8752-79; 6 - Abrasive disk; 7- Driving shaft, 8 - Screw with left-hand thread, 9 - Nipple coupling, 10 – Feeding funnel lid, 11 – Discharge door; 12 - Indicator; 13 – “START” button; 14 – “STOP” button, 15 – Time relay, 16 - Lever shutoff device, 17 - V-belt, 18 - motor with drive pulley, 19 - Base, 20 – Drain tube, 21 - Grounding boss; 22 – Peel pulp collector.

Machine operation is based on peeling potatoes and other root crops under mechanical action of working tools.

Peeling process consists in mechanical action of processing tools on the product (abrasive tray and internal chamber with holes) and water. Peel pulp is removed through a hole in the bottom of the machine through drain pipe directly or through peel pulp collector mounted under the drain pipe.

Use the knob of time relay to set the required operating cycle time. Switch ON the machine by pressing “START” button. Pour water into the housing through the hole in the funnel providing total consumption of not more than one liter of water per one kilogram of the product to be peeled.

Open the feeding lid, load the previously washed and peeled product into the housing. Close the lid.

Perform product peeling and monitor normal water and peel pulp removal from the machine. Clean the grid of peel pulp collector several times.

Peeling efficiency should be checked visually. After the end of peeling process, place a container for collecting the peeled product under the tray of discharge door, shut off water supply to the housing, carefully open the discharge door and take the peeled product out.

After discharging the entire portion of the product, close the discharge door. To peel the next portion of the product, repeat the operations. At the end of peeling, turn OFF the machine by pressing “STOP” button and stop water supply to the housing.

At the end of the work, turn circuit breaker OFF.

The peeled product is subjected to additional peeling (removal of “eyeholes” and the remaining peel) by hand.

The place of machine installation should ensure safety and ease of operation and maintenance. It should comply with sanitary standards, fire safety requirements, labor safety instructions and mounting guide.

The machine should be maintained clean and entirely assembled. It is allowed to use hair brushes or cloth for cleaning.

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After machine unpacking, check delivery set in accordance with paragraph 1.3 of Operating Manual.

Mounting

The place of machine installation should ensure safety and ease of operation and maintenance. It should comply with sanitary standards, fire safety requirements, labor safety instructions and mounting guide.

The machine should be installed on a foundation and secured with four self-tapping screws, anchors and washers.

All the works upon machine connection to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, “Rules for Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are obfed:

- Observance of all the requirements of the “Operation Manual” regarding the machine.

- Mounting and putting into operation is performed by specialists of servicing company or by specialists of another company under written permission of the manufacturer.

- Handing over (sending) a copy of properly drawn-up “Act of putting the machine into operation” to manufacturing company within 10 days from the day of putting the machine into operation in order to provide warranty registration.

- Performing monthly maintenance under the “Operation Manual”.

- Handing over (sending) a copy of properly drawn-up “Damage Claim”.

Monthly maintenance operations in accordance with the requirements of the “Operation Manual” are NOT warranty maintenance and should be performed at consumer’s expense by specialized companies under a preliminary agreement.

In case of violation of at least one of the aforementioned conditions, the manufacturer disclaims their warranty liabilities.

Note: the drawn-up “Act of putting the machine into operation” and “Damage Claim” shall be stamped by a consumer and by the company putting the machine into operation or performing its repair and maintenance.