(+375 163) 42-19-22

(+375 163) 42-26-96

Vertical Sausage Stuffers

- ШКВ-3

- ШКВ-5

Vertical sausage stuffers ShKV are designed for stuffing sausage casings at trade and public catering establishments.

Includes 4 nozzles: Ø10 mm, Ø20 mm, Ø30 mm, Ø40 mm!

Manufactured according to TO BY 200166490.016-2020.

Manual drive.

Recommended operating temperature from +1 to +300С

Vertical sausage stuffers ShKV have DECLARATION ON CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS.

Main technical characteristics:

Parameter name | Value | |

ShKV-3 | ShKV-5 | |

Volume, l | 3 5 | |

Mass of the loaded product, kg, not more than | 7 | 11 |

Cylinder dimensions, mm diameter cylinder height |

Ø140 200 |

Ø140 320 |

Overall dimensions, mm, not more than width length height |

340 570 |

340 690 |

Filler weight, kg, not more than | 11 | 12 |

Composition and completeness

Name | Quantity per stuffer, pcs | |

ShKV-3 | ShKV-5 | |

Vertical sausage stuffer assembly (with clamping nut and handle removed) | 1 | 1 |

Handle | 1 | 1 |

Clamping nut | 1 | 1 |

Accessory set | ||

Nozzle Ø10 mm | 1 | 1 |

Nozzle Ø20 mm | 1 | 1 |

Nozzle Ø30 mm | 1 | 1 |

Nozzle Ø40 mm | 1 | 1 |

Container set | ||

Packaging box | 1 | 1 |

Documentation | ||

Manual ShKV РЭ | 1 | 1 |

The device and operation:

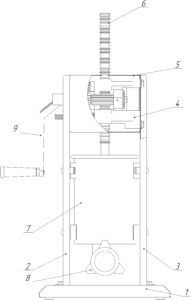

The stuffers are a platform 1, left 2 and right 3 stands, on which a cylinder 7 is fixed with a piston 6 moving in the internal volume. In the lower part of the cylinder 7 there is an outlet, to which a nozzle of the required diameter is attached with a clamping nut 8. To supply the product, the translational movement of the piston 6 is used, which is provided by a mechanical gearbox located in the drive 4. The piston sets the handle 9 in motion.

1 - platform; 2 – left stand; 3 - right stand; 4 - drive; 5 - drive casing; 6 - piston; 7 - cylinder; 8 - clamping nut; 9 - handle.

Operating procedure

Install the handle of the stuffer on the drive, remove the cylinder from the stuffer housing. Install a nozzle of the required diameter on the lower part of the cylinder and secure with a clamping nut. Fill the cylinder with minced meat and install it in the stuffer housing. Put the casing filled with minced meat on the nozzle. Transfer the handle to the low speed drive and turn it clockwise - the stuffing will start to come out of the nozzle and fill the casing. Stuffers must be sanitized after each use. Remove dirt with a damp cloth dampened with soapy water. After cleaning, wipe the filler surfaces with a dry cloth.

Do not use abrasive materials to clean fillers surfaces.

The warranty period of operation is 24 months from the date of transfer of the product to the consumer, unless otherwise provided by the contract, the sale of mixers to the consumer, unless otherwise provided by the contract.