(+375 163) 42-19-22

(+375 163) 42-26-96

MT-60 TWO-SPEED DOUGH MIXER

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

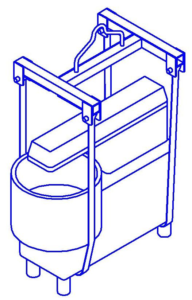

MT-60 dough mixer with two-speed motor is designed for intensive mixing of yeast and stiff dough. It can be applied in small baking factories, pastry shops and in public catering facilities.

First speed is used for dough ingredients mixing (preventing flour from dusting). The second speed (increased) is used for intensive kneading of any dough at moisture content of 39-54%. Two-speed motor allows increasing machine’s capacity in comparison with similar machines made by other manufacturers.

The machine is manufactured in “У” climatic modification (moderate climate) and placement category 3 (enclosed rooms with natural ventilation) as per GOST 15150-69 for operation at temperatures from +1°С to +40°С.

The mixer is equipped with raisable head with kneading tool.

MT-60 dough mixer is manufactured in accordance with the requirements of STB ISO 9001-2015. It is compliant with Customs Union Declaration of Conformity, the Certificate of Conformity to Directives of the European Union – CE and with the DECLARATION ON CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS.

Basic technical parameters of the machine

|

Machine package set

Model | Item name | Quantity |

МТ-60 | Dough mixer | 1 |

Support | 4 | |

Input device: automatic switch of type BA 47-29, 3 poles, 400 V, 4.0 A, 50 Hz, time-current characteristic “C” Automatic switch of specified parameters is an integral part of the machine. Violation of this requirement may result in machine malfunction. | 1 Note: included by customer | |

Cable H05VV5-F5G1 (or a similar one) | overall length - 3.2 m Note: for machine connection to automatic switch | |

Set of packaging materials | ||

Package box | 1 | |

Documentation | ||

МТ-60 РЭ | Operating manual | 1 |

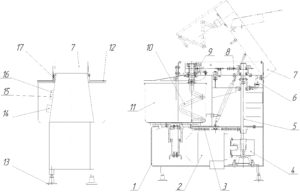

Dough mixer composition and operation

The trough filled with dough mix is rotated by electrical drive. Simultaneously with trough rotation, the screw rotates and mixes the dough. The trough rotating around its axis together with the screw rotating inside the trough ensure thorough dough kneading.

The machine includes a removable kneading tool (screw), that makes sanitary treatment easier.

Kneading tool can be raised. This provides convenience of dough extraction from the trough.

Electrical circuit provides three automatic operation modes:

“1” - In this mode, the machine works at first (lower) tool rotation speed (trough speed - 10 rpm., screw speed - 100 rpm.);

“2” - In this mode, the machine works at the second (higher) tool rotation speed (trough speed - 20 rpm, screw speed - 201 rpm.);

“Auto” - In this mode, after pressing “START” button, the machine firstly works at the first (lower) speed during the time determined by time relay located on electrical equipment board (120-140 seconds). After that, the machine automatically switches to the second (higher) tool rotation speed and operates at this speed until “STOP” button is pressed.

To prevent the personnel from injuries caused by rotating screw, the trough is equipped with a cover with microswitches. When any of them is actuated, the machine stops.

during operation in any of the three modes, when trough cover is raised (SQ2 microswitch control), the machine stops, and after lowering the cover, it resumes operation. When flap case is raised (SQ1 microswitch control), or when trough fixture is loosened (SQ2 proximity switch control), machine cycle gets interrupted. To start a new cycle, press “START” button after all locks are removed.

1 – housing; 2 – electric motor; 3, 8 – chain drives; 4 – reduction unit; 5 – shaft; 6, 9 - microswitches; 7 – flap case; 10 – screw; 11 – trough; 12 – trough cover; 13 – adjustable support; 14 – operating mode switch; 15 – STOP button; 16 – START button; 17 – clamping screw

Transportation

The packed machine should be transported by any type of covered vehicles, except for aircrafts, in a vertical position, in accordance with goods carriage regulations applicable for these means of transportation.

The machine transportation conditions correspond to group 3 as per GOST 15150-69 and to the temperatures of not below -25℃.

Transportation of the packed MT-60 dough mixer is performed as follows:

After unpacking, dough mixer should be handled and moved using load-lifting equipment of appropriate capacity.

After unpacking the machine should be checked for completeness in accordance with paragraph 1.3 of Operating Manual.

Mounting

The machine should be installed on a flat base (table, cabinet) in an easily accessible place, corresponding to machine’s weight. Adjustable supports should be screwed to housing bottom.

Place of machine installation should not be accessible to children and disabled people.

All works upon machine connection to electric mains and putting into operation should be performed by specialized service company personnel with not lower than “III” electrical safety tolerance group in accordance with “Electric Installation Code”, “Regulations for Operation of Consumer Electrical Installations” of TCP 181-2009 (02230) technical code of common practice and with “Interindustry labor safety rules”, applicable in the Republic of Belarus or in accordance with similar regulatory documents applicable in importing country.

The machine should be connected through input device with built-in automatic circuit breaker with overload current value of Inom. = 4.0 A.

Warranty liabilities

Warranty period is 24 months starting from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period on the following terms:

- All the requirements of “Operating Manual” for the machine are observed.

- Putting into operation and monthly maintenance are performed by a specialized company (under consumer agreement) in accordance with the list of companies or by other repair companies under written manufacturer’s permission.

- Copy (transmission) of the signed “Act of machine commissioning” (Annex И) is handed over (sent) to manufacturing company within 14 days from the day of putting the machine into operation.

- Signed “Damage claim” (Annex K), containing the information on machine malfunction or failure of its parts or components, is sent to manufacturing company.

In case of non-observance of any of the above-mentioned terms, the manufacturing company disclaims all its warranty liabilities.

Note: the signed “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by the company that performs repair and maintenance.