(+375 163) 42-19-22

(+375 163) 42-26-96

TWO-SPEED SPIRAL MIXER МТ-30

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

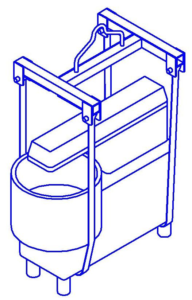

Spiral mixer МТ-30 with two-speed motor is designed for intensive mixing of yeast and stiff dough at small bakeries, confectionaries and catering enterprises. The first speed is for mixing the ingredients (to prevent spraying of flour). The second (increased) speed is for kneading dough of any thickness. The use of two-speed motor allows to increase the productivity of the machine as compared with similar machines from other manufacturers.

This machine is equipped with removable bowl and lifting head with kneading tool.

Main technical specifications of the machine

Parameter | value |

Simultaneous loading of dough ingredients, kg, not more | 25 |

Productivity, kg/h, not less | 110 |

Power of the installed motor, kw/h | 0,8/1,32 |

Nominal power consumption, kw, not more | 1,3/1,8 |

Bowl capacity, l | 32 |

Overall dimensions, mm, not more: |

|

Supply main: | three-phase |

Weight, kg, not more | 115 |

Machine arrangement

Designation | Name | Quantity |

МТ-30 | Dough mixer | 1 |

ШХ-2К.1.12.00.000 | Support | 4 |

Input device with built-in automatic switch of type BA 47-29, 50 Hz, time-current characteristic “C”, 230/415 TU 2000 АГИЕ.641.235.003 2 poles, 5.0 А An automatic switch of specified parameters is an integral part of the machine. Violation of this requirement may result in machine malfunction. | 1 Note: included by customer | |

3SD6 outdoor-mounted control board with “neutral bus” and grounding bus for double-pole automatic switch | 1 Note: included by customer | |

Cable H05VV5-F5G1 (or a similar one) | 3.2 m Note: for machine connection to automatic switch | |

Package set | ||

Package box | 1 | |

Documentation | ||

МТ-30 РЭ | Operating manual | 1 |

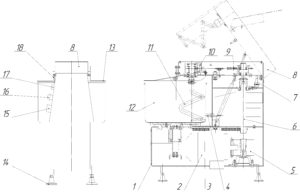

Dough mixer arrangement and operation

The trough filled with dough mix is rotated by electric drive. Simultaneously with trough rotation, screw rotates and mixes the dough. The trough rotating around its axis together with the screw rotating inside the trough ensure thorough dough kneading.

The kneading tool (screw) of the machine is removable, which makes sanitation easier.

The kneading tool can be raised. This provides convenience of dough extraction from the trough.

Electrical circuit provides three automatic operation modes:

“1” - In this mode, the machine operates at the lower first speed of tool rotation (trough rotation speed - 10 rpm., screw rotation speed - 100 rpm.);

“2” - In this mode, the machine operates at the higher second speed of tool rotation (trough rotation speed - 20 rpm, screw rotation speed - 201 rpm.);

“Auto” - In this mode, after pushing “START” button, the machine firstly operates at the first (lower) speed during the time determined by time relay located on electrical equipment panel (factory default setting is 90 seconds). After that, the machine automatically switches to the second (higher) tool rotation speed and operates at this speed until “STOP” button is pushed.

To prevent the personnel from injuries, the trough is equipped with a cover with microswitches. When any of them is actuated, the machine stops.

When the trough cover is raised during operation in any of the three modes, the machine stops and after lowering the cover, it resumes operation according to cycle timing (SQ2 microswitch control). When flap case is raised (SQ1 microswitch control), or when trough fixation is loosened (SQ2 proximity switch control), the machine cycle gets interrupted. To start a new cycle, push “START” button after all locks removal.

1 - housing; 2 - electric motor; 3,9 - chain drives; 4 - proximity switch; 5 - reduction unit; 6 - shaft; 7,10 - microswitches; 8 -flap case; 11 - screw; 12 - dough trough; 13 - trough cover; 14 - adjustable support; 15 - operation mode switch; 16 - “STOP” button; 17 - “START” button; 18 - clamping screw

Transportation

The packed machine is transported by any covered means of transportation, excluding air transport, in a vertical position, in accordance with goods carriage regulations applicable for these types of transport.

Transportation conditions of the machine correspond to conditions group 3 as per GOST 15150-69 and to the temperatures of not below -25℃.

Transportation of the packed MT-30 dough mixer is performed as follows:

After unpacking, the dough mixer should be lifted and moved by means of load-lifting equipment of appropriate capacity.

After unpacking the machine should be checked for completeness in accordance with clause 1.3 of its Operating Manual.

Mounting

The machine is installed in an easily accessible place on a flat base (table, cabinet), corresponding to the machine weight. Adjustable supports should be screwed to housing bottom.

Place of machine installation should not be accessible to children and disabled people.

All works upon machine connection to electric mains and putting into operation should be performed by specialized service company personnel in accordance with “Electric Installation Code”, “Regulations for Operation of Consumer Electrical Installations” of TCP 181-2009 (02230) technical code of common practice and “Interindustry labor safety rules”, that are applicable in the Republic of Belarus or in accordance with similar regulatory documents applicable in an importing country.

The machine should be connected through an input device with built-in automatic circuit breaker with overload current value of Inom. = 3.0 A.

Warranty liabilities

Warranty period (24 months) starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company eliminates malfunctions of the equipment during warranty period on the following terms:

All the requirements of “Operating Manual” for the machine have been observed.

Copy of signed “Act of machine commissioning” has been handed over (sent) to manufacturing company within 14 days from the day of putting the machine into operation.

Signed “Damage claim”, containing the information on machine malfunction, failure of its parts or utilities, has been sent to manufacturing company.

In case of non-observance of any of the above-mentioned terms, the manufacturing company disclaims all its warranty liabilities.

Note: the signed “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by the company that performs repair and maintenance.