(+375 163) 42-19-22

(+375 163) 42-26-96

ROOT CROP PEELER МОК-400

- Люк

- Замок

MOK-400 root crop peeler is designed for mechanical peeling potatoes and root vegetables (beets, carrots) under the action of cleaning tools at catering facilities. It is manufactured in floor standing version with stainless steel facing.

Monolithic housing design!

The peeler is manufactured with a brand-new unloading hatch, new locking mechanism and is equipped with a brand-new abrasive disk of high-strength low-wear material. The new abrasive disc does not require balancing.

The machine is manufactured in УЗ modification (moderate climate, free room ventilation) in accordance with GOST 15150-69 for operation at temperatures from +1°C to +40°C, in accordance with the requirements of STB ISO 9001-2015 and has the Declaration of Conformity of the Eurasian Economic Union (see Annex).

Basic technical specifications of the machine

Parameter name | МОК-400 |

Capacity (kg/h, minimum*) | 400 |

Product peeling efficiency (%, minimum*) | 90 |

Volume of simultaneously loaded product (kg, maximum*) | 14 |

Volume of product wastes during peeling (%, maximum*) | 20 |

Rated power consumption (kW, maximum) | 0,82 |

Overall dimensions (mm, maximum) - length - width - height |

605 530 835 |

Power supply: - current type - rated voltage (V) - current frequency (Hz) | three-phase alternating 380 50 |

Cold water consumption (l/kg, maximum*) | 1,5 |

Duration of processing cycle (minutes, maximum) | 2,0 |

Weight (kg, maximum) | 46 |

Control unit | Remote, on a tray |

* - Capacity is checked at 90% of completely peeled potatoes. A tuber is considered peeled when peel remains in the recesses and in no more than three unpeeled areas (with maximum size from 1 to 3 mm) on the remaining surface (values for root crops (beets, carrots) are not specified).

Composition of the machines

Model designation | Description | Quantity per machine |

МОК-400 | ||

МОК-400 | Root crop peeler consisting of: grid, abrasive disk, pulp collector | 1 |

Wire ПВС 4х1,01х1,0, black (or other similar wire), overall length (m) | 3,6 Note: Not included in delivery set. Purchased separately | |

Set of spare parts | ||

МОК-400.60.000 | Abrasive disk | 1 |

Set of mounting parts | ||

Expansion anchor РРК14 Coated self-tapping screw with hexagonal head, 10х90 Washer А.10.21.08Х18Н10 GOST 11371-78 Filling hose (1 m) | 4 4

4 1 | |

Input device with automatic circuit breaker of type ВА 47-29, 400V, ~50Hz, 3 poles, 2.0А, time-current characteristic «С», ТУ 2000 АГИЕ.641.235.003 Automatic circuit breaker of specified type is an integral part of the machine. Non-fulfillment of this requirement may cause damage to the machine. | 1 Note: added by customer | |

Outdoor installation box 3SD6 with neutral bus and ground bus for three-pole circuit-breaker | 1 Note: added by customer | |

Set of packaging | ||

Package box | 1 | |

Documentation | ||

МОК-400 ОМ | Operating manual | 1 |

МОК-400 Д1 | Quick user’s guide | 1 (included in OM) |

МОК-400 Д2 | Safety instructions for root crop peeler usage | 1 (included in OM) |

Composition and functionality of root crop peeler

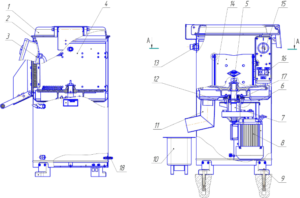

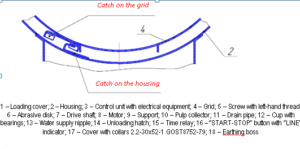

The machine consists of a housing with a grid, loading cover, a motor and pulp collector.

Machine operation is based on peeling potatoes and other root crops under mechanical action of working tools.

Water is poured into the housing through a hose with a nipple. General consumption - not more than 1.5 liters of water per kilogram of product being peeled (water pressure - 260 kPa).

Open the loading cover, load the previously washed and cleaned product into the housing. Close the cover. Using time relay handle, set the required cycle duration. run the machine by pressing “START” button.

Perform product peeling and monitor the normal water and pulp removal from the machine. Clean the grid of pulp collector several times.

Upon completion of peeling process, place a container for peeled product collection under unloading hatch, stop water supply, carefully open the unloading hatch door and unload the peeled product. Peeling quality is checked visually.

After peeling and unloading the entire portion of the product, stop the machine by pressing “STOP” button on remote control unit. After unloading the entire portion of the product, close the unloading hatch door. To peel the next portion of the product, repeat the operation. At the end of operation, turn OFF the circuit breaker.

The peeled product should undergo manual final peeling (removal of “eyes” and the remaining peel).

The machine should be maintained clean and entirely assembled. It is allowed to use hair brushes or cloth for cleaning.

Transportation

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After unpacking, check the completeness of delivery in accordance with paragraph 1.3 of the Operating Manual.

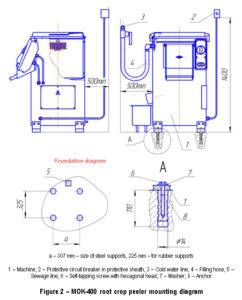

Mounting

The place of machine installation should ensure safety and ease of operation and maintenance, and should comply with sanitary standards, fire safety requirements, labor safety instructions and wiring diagrams.

The machine should be mounted on a foundation and secured on it using four self-tapping screws, anchors and washers.

All the works upon connecting the machine to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for the Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of the importing country.

Warranty liabilities

Warranty period is 24 months (warranty does not cover the abrasive disk). It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are observed:

- Observance of all the requirements of “Operating Manual” regarding the machine.

- Putting into operation and monthly maintenance is performed by a specialized company (under consumer agreement) in accordance with the list of companies or by other repair companies under written permission of the manufacturer.

- Handing over (sending) the copy of signed “Act of machine commissioning” (Annex И) to manufacturing company within 14 days from the day of putting the machine into operation.

- Sending (handing over) the “Damage claim” (Annex К), containing the information on machine malfunction, failure of its parts or utilities.

In case of non-observance of any of the above-specified conditions, the manufacturing company disclaims all its warranty liabilities.

Note: the drawn-up “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by repair/maintenance company.