(+375 163) 42-19-22

(+375 163) 42-26-96

MP-10 and MP-10-01 SEVEN-SPEED PLANETARY MIXERS

MP-10 and MP-10-01 seven-speed planetary mixers are designed for kneading dough of various consistency in the shops for baking, making bread, pizza, cookies, pastries, cakes; mixing pastes, purees, mayonnaise, sauces and other food mixtures; whipping cream, ice cream, various creams, mixing minced meat, etc. at food industry enterprises and other organizations for food production.

The mixers are equipped with three quick-change tools: whisk, blade and hook, that allow shaking, mixing or kneading any food product.

The built-in automatic rotation speed controller allows setting the required tool speed for various mixing types.

Removable trough and quick mounting and changing of tools provide reduction of operator’s working hours. Mixer base is painted with scratch-resistant and easy to clean paint. Food-contacting parts are made of stainless steel. Mixers should be installed on a support (cabinet), that provides ergonomic access to control tools.

When manufacturing confectionery and bakery products, moisture content in the dough should be at least 55%.

The mixers are manufactured in placement category 4 as per GOST 15150-69 and in “УХЛ” (boreal climate) climatic modification for operation at temperatures from +1°C to +40°C.

The machines are approved in accordance with Eurasian Conformity Certificate (Annex) and EU Directive Conformity Certificate - CE.

Basic technical parameters of the mixers

Parameter description | МP-10 | МP-10-01 |

Trough volume (l) | 10 | 10 |

Capacity (kg/h) - dough kneading - cream whipping |

16 40 |

16 40 |

Rated power consumption (W, max.) | 550 | 550 |

Installed power (W) | 370 | 370 |

Rated voltage (V) | 380 | 220 |

Current type | three-phase alternating | three-phase alternating |

Current frequency (Hz) | 50 | 50 |

Tool rotation speed (minutes-1) min max |

90 500 |

90 500 |

Trough rotation speed (minutes-1) min max |

25 140 |

25 140 |

Number of speeds | 7* | smooth adjustment |

Overall dimensions (mm, maximum): length width height |

570 420 780 |

570 420 780 |

Масса, кг | 45 | 47 |

Simultaneous loading of dough ingredients (kg, max.) | 4 | 4 |

* Tool operation mode

* You can adjust tool rotation speed using speed selector depending on operation performed and the tool used:

|

Mixer package set

Item name | МP-10 | МP-10-01 |

Mixer | 1 | 1 |

Automatic switch of type BA 47-29, 3 poles, 400 V, 50 Hz, 2.5 A, time-current characteristic “C” Automatic switch of specified parameters is an integral part of the machine. Violation of this requirement may result in machine malfunction. | 1 Note: included by customer | - |

3SD6 exposed installation board with “zero bus” and ground bus for a three-pole circuit breaker | 1 Note: included by customer | - |

Cable H05VV5-F5G1 (or a similar one), overall length (m) | 3,2 Note: for machine connection to automatic switch | - |

Set of accessories | ||

Whisk | 1 | 1 |

Blade | 1 | 1 |

Screw | 1 | 1 |

Set of packaging materials | ||

Package box | 1 | 1 |

Documentation | ||

Operating manual | 1 | 1 |

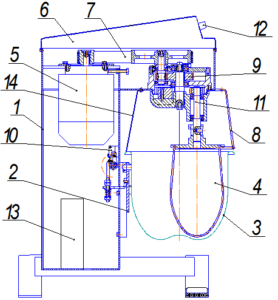

Mixer composition and operation

The mixer consists of a housing where tool rotation drive (including electric motor, belt drive, gearbox) is mounted.

1 - housing; 2 - bracket; 3 - trough; 4 – replaceable tool (blade; whisk; screw); 5 – electrical motor; 6 – cover; 7 – belt drive; 8 – grid; 9 – reduction unit; 10 – switch; 11 – output shaft; 12 – control buttons “START-STOP”; “LINE”; speed switch); 13 – control board; 14 – board

Depending on the work to be done, mount and secure the appropriate tool (whisk, blade, screw) on drive output shaft.

Install the trough on the bracket, put all the necessary ingredients in it. Use the lever to raise the trough to the upper position and lower the grid. Start the mixer by pressing “START” button. The mixer gets started only when the trough is mounted and the cover is lowered.

To avoid splashing and throwing of the product, start operation at a low speed, and then gradually increase it.

At the end of kneading or whipping, use “STOP” button to stop the mixer. Lower the trough with the lever to the bottom position, remove the trough with the mixture from the bracket and remove the processed mixture. Remove the tool only with the trough.

At the end of work, turn off the mixer by switching off the circuit breaker.

Transportation

The mixer should be transported from the place of receipt to the place of installation and mounting in factory package. After unpacking the machine, check the completeness of delivery in accordance with paragraph 1.4 of its Operating Manual.

Mounting

Special conditions for mixer mounting (installation) are not provided. Installation location should not be accessible to children and persons with disabilities. Supporting table should be tough and even.

All works upon machine connection to power line and putting into operation should be performed by specialized service company personnel in accordance with “Electric Installation Code”, “Regulations for Operation of Consumer Electrical Installations” of TCP 181-2009, “Interindustry labor safety rules” applicable in the Republic of Belarus or in accordance with similar regulatory documents applicable in importing country.

Warranty liabilities

Warranty period is 24 months starting from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period on the following terms:

- All the requirements of “Operating Manual” for the machine are observed.

- Putting into operation and monthly maintenance are performed by a specialized company (under consumer agreement) in accordance with the list of companies or by other repair companies under written manufacturer’s permission.

- Copy (transmission) of the signed “Act of machine commissioning” (Annex И) is handed over (sent) to manufacturing company within 14 days from the day of putting the machine into operation.

- Signed “Damage claim” (Annex K), containing the information on machine malfunction or failure of its parts or components, is sent to manufacturing company.

In case of non-observance of any of the above-mentioned terms, the manufacturing company disclaims all its warranty liabilities.

Note: the drawn-up “Act of machine commissioning” and “Damage claim” shall be stamped by the consumer and by repair/maintenance company.