(+375 163) 42-19-22

(+375 163) 42-26-96

MIM-1000М MEAT MINCER

- МИМ-1000М

- МИМ-1000

The equipment is included in the Eurasian Registry of Industrial Products of the Ministry for Industry and Trade of Russian Federation.

The equipment is included in the Eurasian Registry of Industrial Products of EAEU Member States (manufacturer’s identification No. 200166490).

The company is included in the Registry of bona fide partners of BelCCI.

Our company has mastered manufacturing of brand-new equipment with account for modern requirements for quality, design and performance!

MIM-1000M meat mincer is designed for grinding lumpy stringy meat in manufacturing of minced meat for sausages and other meat products at public catering facilities, in meat stores and small manufacturing workshops, butcher shops, at the companies for manufacturing cutlets, dumplings, sausages and other semi-finished products.

The mincer is manufactured in UHL4 (moderate climate) modification under GOST 15150-69 for operation at temperatures from +1 to +35°С.

It is remarkable for its reliability, safety and compliance with EAC technical regulations, ease of maintenance and long service life.

MIM-1000М meat mincer is manufactured in accordance with the requirements of STB ISO 9001-2015 and has ЕАС Declaration of Conformity (Annex), Certificate of Conformity to EU Directives - CE.

MIM-1000М mincer provides “Reverse” mode for the case of auger stopping during processing of low-quality meat products. By pressing “Reverse” button, you can return the product to loading neck and then repeatedly process it or remove it from the mincer with no disassembly of blades - grinding plates - auger unit.

Made entirely of high-quality stainless steel.

A belt drive is used in MIM-1000M meat mincer, a silent worm reducer is installed.

Equipped with a removable Enterprise knife and grid system, made of high-quality material that is resistant to damage. The knife and grid are of sufficient thickness to provide many sharpening procedures. Durability of the used components is ensured, provided that sharpening is performed in strict accordance with technical requirements.

Ventilated three-phase motor ensures continuous operation for many hours.

Basic technical parameters of meat mincer

Parameter description | Value |

Performance (kg/h, minimum*) | 1000 |

Installed power (KW) | 5.5 |

Rated power consumption (KW) | 6.5 |

Tray volume (l) | 40 |

Power supply: - current type - rated voltage (V) - current frequency (Hz) |

three-phase, alternating 380 50 |

Overall dimensions (mm, maximum) - length - width - height |

1225 600 1010 |

Weight (kg, maximum) | 152 |

* - Actual capacity of meat mincers depends on the speed of feeding of product pieces to the auger by the operator, the grade of meat being processed, and the quality of tool sharpening.

Machine composition

Designation | Description | Quantity per mincer |

|

MIM-1000 | Meat mincer assembly: housing, tray, pusher, meat mincer (stainless steel neck, auger, grinding plate No.1, blade, nut) | 1 |

|

Set of replaceable parts | |||

MIM-1000.90.001 MIM-1000.90.002 | Grinding plate No.2 Grinding plate No.3 | 1 1 |

|

Set of tools and accessories | |||

MIM-1000.94.001 | Remover | 1 |

|

| Open-end wrench 7811-0125 С1х9 GOST 2841-80 (S=24 for meat mincer removal) | 1 |

|

| Fixed socket ССИ-125 16А 240/380 3Р+РЕ+N, IP 44 Cable 2-NORM (H)05VV-F 5G2.5 (or another similar), overall length (m) |

1 3.6

|

|

Set of spare parts | |||

MIM-1000.20.001 | Blade | 1 |

|

Set of package | |||

| Package box | 1 |

|

Documentation | |||

MIM-1000 OM | Operation manual | 1 |

|

MIM-1000 D1 | Quick user’s guide | 1 (included in OM) |

|

MIM-1000 D2 | Safety instructions for meat mincer usage | 1 (included in OM) | |

Composition and functionality of meat mincer

Meat mincer consists of mincing unit, tray with protection unit, pusher, housing consisting of: electrical motor, reducer, lid, frame, undercarriage and wheeled support. Meat mincer assembly consists of: nut, grinding plate No.1, knife and stainless steel neck where auger rotates.

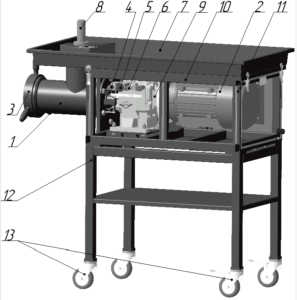

1- meat mincer; 2- electrical motor; 3 – nut; 4 – “Start” button; 5 - “Stop” button; 6 – “Reverse” button; 7 – Tray with protection element; 8 – pusher; 9 – reducer; 10 – lid; 11 – frame; 12 – undercarriage; 13 – wheeled support.

The housing is fastened with cap nuts.

Above the loading opening there is a non-removable safety device with a pusher that prevents operator's hands from contacting the auger during operation.

The processed product should be deboned and cut into pieces. The temperature of the processed product should be +8 ± 2°С. Connective tissues and tendons should be removed from the processed product. If they cannot be separated, they should be cut in several places to avoid forming fibers that are wound around the knife during operation, disrupting the normal operation of meat mincer.

The prepared product should be loaded into the tray, manually fed to the neck of meat mincer, and then pushed to the rotating auger.

Grinding plate parameters

Plate parameter description | Value | ||

Plate No. | |||

1 | 2 | 3 | |

External diameter (mm) | 155 | 155 | 155 |

Hole diameter (mm) | 6 | 4.5 | 8 |

Number of holes (pcs.) | 216 | 348 | 132 |

Transportation

Long-time idle operation of the mincer (with no product loading) is impermissible as dry friction results in damage to clamped blades and grinding plates.

The machine should be transported from the place of receipt to the place of installation and mounting in factory package. After machine unpacking, check delivery set in accordance with paragraph 1.3 of Operating Manual.

Mounting

All the works upon machine connection to power line and putting it into operation should be performed by a representative of servicing company in accordance with “Electrical Installations Code”, TKP 191-2009 “Rules for Operation of Consumers’ Electrical Installations” and “Cross-industry Labor Safety Regulations” applicable in the Republic of Belarus or in accordance with similar applicable regulations of importing country.

Warranty liabilities

Warranty period is 24 months. It starts from the day of putting the machine into operation, but not later than 6 months from the date of machine purchase.

Manufacturing company shall eliminate equipment malfunctions during warranty period, provided that the following conditions are obfed:

- Observance of all the requirements of the “Operation Manual” regarding the machine.

- Mounting and putting into operation is performed by specialists of servicing company or by specialists of another company under written permission of the manufacturer.

- Handing over (sending) a copy of properly drawn-up “Act of putting the machine into operation” to manufacturing company within 10 days from the day of putting the machine into operation in order to provide warranty registration.

- Performing monthly maintenance under the “Operation Manual”.

- Handing over (sending) a copy of properly drawn-up “Damage Claim”.

Monthly maintenance operations in accordance with the requirements of the “Operation Manual” are NOT warranty maintenance and should be performed at consumer’s expense by specialized companies under a preliminary agreement.

In case of violation of at least one of the aforementioned conditions, the manufacturer disclaims their warranty liabilities.

Note: the drawn-up “Act of putting the machine into operation” and “Damage Claim” shall be stamped by a consumer and by the company putting the machine into operation or performing its repair and maintenance.