(+375 163) 42-19-22

(+375 163) 42-26-96

DOUGH SHEETER TRM-500

The company is included in the Register of bona fide partners of the Belarusian Chamber of Commerce and Industry.

Dough sheeter TRM-500 is designed for dough sheeting when preparing pizza, bread, cakes, dumplings at trade and public catering establishments.

Produced in accordance with TS BY 200166490.044-2021 in climatic version UHL 4 in accordance with GOST 15150.

- 2 rolls (length 500 mm) made of special non-stick material;

- the spread of the rollers is adjustable 0 ... 4 mm;

- uniform rolling;

- workpiece size 350 * 50 mm., weight no more than 0.35 kg;

- technical productivity 120 kg/h;

- asynchronous motor with a power of 250 W, 220 V, permissible continuity of operation before unloading 8 hours;

- housing made of high-quality stainless steel, compact (with the possibility of fastening to the wall);

- easy cleaning. All measures for safe operation are taken into account;

- controllable with a pedal.

Dough sheeter TPM-500 is manufactured in accordance with the requirements of STB ISO 9001-2015, has a Declaration of Conformity EAC, DECLARATION ON CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS.

Main technical characteristics of the dough sheeter:

Parameter name | ТРМ-500 |

Installed power, W | 250 |

Rated power consumption, W | 420 |

Occupied area, m2 | 0,26 |

Mass limits of dough pieces, kg | 0,35 |

Power supply network: type of current rated voltage, V current frequency, Hz | single-phase alternating 220 50 |

Overall dimensions, mm, not more than length width height |

700 370 430 |

Mass, kg, not more than | 30 |

The composition of the dough sheeter:

Designation | Name | Quantity, pieces |

ТРМ-500 | Dough sheeter | 1 |

| Corbel | 2 |

| Screws М6х12.019 GOST ISO 7380-1-2014 | 6 |

| Pedal TFS-01 | 1 |

Accessory set |

| |

| L-shaped imbus key 7812-0373 Х9 GOST 11737-93 | 1 |

Sets |

| |

ТРМ-500.10.000 | Packaging set | 1 |

Documentation |

| |

ТРМ-500 РЭ | Manual | 1 |

ТРМ-500 Д1 | Instructions for handling dough sheeters ТРМ-500 | 1 (as part of РЭ) |

ТРМ-500 Д2 | Safety instructions for the operation of dough sheeters ТРМ-500 | 1 (as part of РЭ) |

The device and operation of the dough sheeter

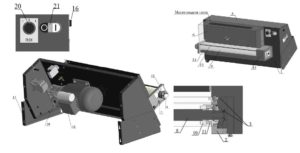

The machine consists of a stainless steel housing 1 and a rolling mechanism. A drive is installed in the housing, consisting of a motor 18, a worm gear 19. The rolling mechanism consists of a transmission that includes a bevel gear 2, shafts 9 mounted on axes 8, rolling thickness adjustment knobs 4. The principle of operation of the machine is to skip the dough between the shafts 9, the gap between which is adjusted using the rolling thickness adjustment knob. For the safety of the operator, the rolling mechanism is enclosed by a transparent protective cover 6.

1 - housing; 2 - bevel gear; 3 - hub; 4 – rolling thickness adjustment knob;

5 - shield; 6 – protective cover; 7 - fixing spring; 8 - axis; 9 - shaft; 10 – coupling clutch;

11 - coupling clutch; 12 - support; 13 - connection; 14 - scraper; 15 - casing; 16 - fuse;

17 - corbel; 18 - motor; 19 - worm gear;

20 - switch; 21 - button “Start” – “Stop”.

Pour a portion of flour onto the shaft 9. Insert the plug into the socket. The indicator on the “Start” – “Stop” button will light up. Press the “Start” button. Switch on the machine by turning switch 20 to position “II”. Shafts 9 will start moving. Set the adjustment knob 4 to the maximum thickness of the roll and flattening the portion of dough abundantly floured, put it on the receiving platform. Accept the rolled workpiece at the exit platform. To obtain a smaller thickness of the dough roll, set the required gap of the shafts 9 with the adjustment knob 4.

In order to set the gap with the adjustment knob 4, you must first pull it out and then turn it.

Puff pastry can only be rolled out on the maximum diluted shafts.

At the end of work on the machine, turn switch 20 to position “0”. Press the “Stop” button. Remove the plug from the socket.

To use the pedal, after pressing the “Start” button, set the switch 20 to the “I” position. Starting the motor is done by pressing the pedal, stopping the motor - by removing the foot from the pedal.

Transportation

The machine must be transported from the place of receipt to the place of installation and assembly in the manufacturer's packaging. After unpacking the machine, it is necessary to check the completeness of the delivery in accordance with clause 1.3 of the Operation Manual.

Mounting

The installation site of the machine must guarantee the safety and ensure the convenience of operation during its operation and maintenance, and must also comply with fire safety and safety regulations, requirements. It should exclude its sliding, overturning, turning over in any mode of operation.

All work on connecting the machine to the power supply network and putting it into operation must be performed by a representative of a specialized service organization, in accordance with the current in the Republic of Belarus: “Electrical Installation Rules”, TKП 181-2009 “Rules for the technical operation of electrical installations of consumers”, “Intersectoral rules for labor protection”, or in accordance with similar applicable regulatory documents of the importing country.

Warranty

Warranty period - 24 months from the date of putting the machine into operation, but no later than 6 months from the date of purchase of the machine.

During the warranty period, the manufacturer eliminates failures and malfunctions in the operation of the equipment only on condition:

- Compliance with all requirements of the “Operation Manual” of the machine.

- Installation and commissioning was carried out by the specialists of the service center, or by specialists of another organization with the written permission of the manufacturer.

- Transfer (sending) to the manufacturer a copy of the completed “Equipment Commissioning Certificate” issued in full within 10 days from the date the machine was put into operation to put the equipment on warranty records.

- Carrying out monthly maintenance according to the “Operation Manual”.

- Transfer (shipping) to the manufacturer of the completed “Reclamation Act” in full.

Monthly maintenance works, in accordance with the requirements of the Operation Manual, are not warranty works and are carried out at the expense of the consumer by specialized organizations under a preliminary agreement between them.

If at least one of the above points is violated, the manufacturer disclaims warranty obligations.

Note: the issued “Equipment Commissioning Certificate” and “Reclamation Certificate” must be certified by the seal of the consumer and the enterprise that commissions or repairs and maintains.