(+375 163) 42-19-22

(+375 163) 42-26-96

BONE SAW FOR MEAT PRODUCTS PLM-400

- ПЛМ-400

- ПЛМ-160 ПЛМ-240

The company is included in the Register of bona fide partners of the Belarusian Chamber of Commerce and Industry.

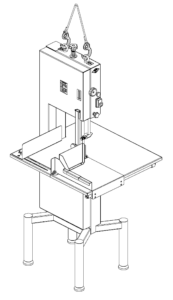

Band saw for meat products PLM-400 is designed for quick cutting of chilled and frozen meat, as well as meat with bones or bones into portions of various sizes.

Produced in climatic version UHL 4 in accordance with GOST 15150-69.

It is distinguished by reliability, safety and compliance with the technical regulations of the Customs Union, ease of maintenance and long service life.

Comes with 2 saw blades!

The housing is made of high quality stainless steel, floor version, on four adjustable feet, with which you can set the machine on an uneven surface.

Maximum cutting height - 420 mm, cutting width - 260 mm.

IMPORTANT! Saw PLM-400 is equipped with two independent movable tables, a mechanism for automatic return of tables to their original state. The ability to move tables both independently and together.

Pulleys are made of stainless steel. Provided with protection against blades’ runaway.

Saw ПЛМ -400 is manufactured in accordance with the requirements of STB ISO 9001-2015, has a Declaration of Conformity EAC, DECLARATION ON CONFORMITY OF PRODUCTS TO THE REQUIREMENTS OF TECHNICAL REGULATIONS.

Main technical characteristics of the saw:

Parameter name | PLM-400 |

Technical productivity, kg/h* | 500 |

Electricity consumption, kW | 1,91 |

Installed power, kW | 1,5 |

Length, width, blade’s thickness, mm, teeth per inch | 3280х20х0,6х4 3280х20х0,56х3 |

Cutting height, not more than, mm | 420 |

Power supply network: type of current rated voltage, V current frequency, Hz | three-phase alternating current 380 50 |

Overall dimensions, mm, not more than length width height |

1 025 1 015 1 990 |

Weight, kg, not more than | 150 |

* - The technical productivity of the saw depends on the feed rate of the product by the operator, the size, density and grade of the processed pieces of the product.

The composition of the saw:

Designation | Name | Quantity, pieces | |

ПЛМ-400

| Band saw with blade 3280x20x0.6x4 mm | 1 | |

Cable H05VV5-T5G1 (or other with similar characteristics), total length 3.6 m | 1 | ||

Spare parts set |

| ||

ПЛМ-240.14.002 | Bar | 1 | |

Accessory set |

| ||

Band saw blade 3280x20x0.56x3 mm | 1 | ||

ПЛМ-400.00.035 | Key 7811-0121 C 1x9 GOST 2841-80 | 1 | |

Eyebolt M12 GOST 4751-73

Stationary socket ССИ-115 16A, 240/380V, 3P+PE+N, IP44 | 2

1 | ||

Packaging set | |||

ПЛМ-400.95.000 | Package | 1 | |

Documentation |

|

| |

ПЛМ РЭ | Operation manual | 1 | |

ПЛМ Д1 | Memo on the saw handling | 1 (as part of RE) | |

ПЛМ Д2 | Safety instructions for saw operation | 1 (as part of RE) | |

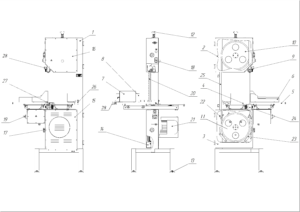

The device and operation of the saw

The saw is driven by an electric motor 21. Pulleys 10 drive the band saw blade 20. The tension of the band saw blade is carried out by rotating the nut 12. The product is cut by passing it through the band saw blade 20. The cutting width can be adjusted using the cut limiter 8. For cutting the last portion of the product, it is necessary to use a device for cutting the last portion of the product 7. For the convenience of working on the saw, depending on the height of the cut of the product, it is necessary to optimally set the protective bar 9 in height and fix it with the petal handle 28.

1 - housing; 2 - top door; 3 - bottom door; 4 - tabletop 1; 5 - tabletop 2; 6 - limit stop;

7 - device for cutting the last portion of the product; 8 - cut limiter; 9 - protective bar;

10 - driven pulley; 11 - leading pulley; 12 - nut; 13 - support; 14 - tray; 15 - motor shield;

16 - lid; 17 - pawl; 18 – “Start-Stop” button; 19 - protection device (circuit breaker);

20 - bandsaw; 21 - electric motor; 22 - brushes; 23 - mudguard; 24 - shield; 25 - blade casing;

26 - latch; 27 - guide bar; 28 - petal handles.

ATTENTION!

To obtain the best sawing results, an ultra-sharp cutting edge must be run in. It is recommended to start work with a feed force of 50% of the calculated one.

After 15-20 minutes of sawing, increase the load to 100% for the next 20 minutes. The run-in time may increase, depending on the material being processed.

If a malfunction is detected in the saw operation, it is necessary to turn off the power supply and not to turn on the saw until the malfunction is eliminated.

Transportation

The machine must be transported from the place of receipt to the place of installation and assembly in the manufacturer's packaging by all types of covered transport in an upright position, with the exception of air transport, in accordance with the rules for the carriage of goods in force for this type of transport.

After unpacking the machine, it is necessary to check the completeness of the delivery in accordance with clause 1.3 of the Operation Manual.

Lifting and moving the saw after unpacking should be carried out using lifting devices of the appropriate load capacity.

Mounting

The installation site of the saw must guarantee the safety and ensure the convenience of operation during its operation and maintenance, and must also comply with fire safety and safety regulations, requirements. It should exclude its sliding, overturning, turning over in any mode of operation.

All work on connecting the machine to the power supply network and putting it into operation must be performed by a representative of a specialized service organization, in accordance with the current in the Republic of Belarus: “Electrical Installation Rules”, TKП 181-2009 “Rules for the technical operation of electrical installations of consumers”, “Intersectoral rules for labor protection”, or in accordance with similar applicable regulatory documents of the importing country.

Warranty

Warranty period - 24 months from the date of putting the machine into operation, but no later than 6 months from the date of purchase of the machine.

During the warranty period, the manufacturer eliminates failures and malfunctions in the operation of the equipment only on condition:

- Compliance with all requirements of the “Operation Manual” of the machine.

- Installation and commissioning was carried out by the specialists of the service center, or by specialists of another organization with the written permission of the manufacturer.

- Transfer (sending) to the manufacturer a copy of the completed “Equipment Commissioning Certificate” issued in full within 10 days from the date the machine was put into operation to put the equipment on warranty records.

- Carrying out monthly maintenance according to the “Operation Manual”.

- Transfer (shipping) to the manufacturer of the completed “Reclamation Act” in full.

Monthly maintenance works, in accordance with the requirements of the Operation Manual, are not warranty works and are carried out at the expense of the consumer by specialized organizations under a preliminary agreement between them.

If at least one of the above points is violated, the manufacturer disclaims warranty obligations.

Note: the issued “Equipment Commissioning Certificate” and “Reclamation Certificate” must be certified by the seal of the consumer and the enterprise that commissions or repairs and maintains.