(+375 163) 42-19-22

(+375 163) 42-26-96

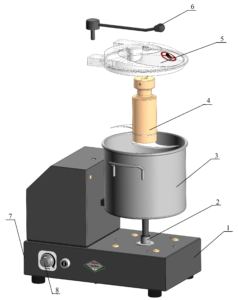

CUTTER KM-9

The company is included in the Register of bona fide partners of the Belarusian Chamber of Commerce and Industry.

The cutter KM-9 is designed for quick chopping, mixing and whipping of products, preparation of minced meat, creams, pates, sauces, mousses, etc. in catering establishments and small processing enterprises.

Produced in accordance with TS BY 200166490.046-2021 in climatic version UHL 4 in accordance with GOST 15150 for operation at temperatures from plus 1 to 350C.

- speed controller;

- a special hole in the lid for adding the necessary ingredients during operation;

- food processing takes less than 3 minutes;

- convenient locking of the lid with a special lever.

LOOK here!

The cutter KM-9 is produced in accordance with the requirements of the STB ISO 9001-2015 standard, has a Declaration of Conformity EAC.

Main technical characteristics of the cutter:

Parameter name | Value |

Installed power, W | 700 |

Rated power consumption, W | 1000 |

Overall dimensions, mm, not more than length width height |

475 315 405 |

Bowl capacity, l | 9 |

Weight, kg, not more than | 26 |

Power supply network: type of current rated voltage, V current frequency, Hz | single-phase alternating 230 50 |

The composition of the cutter:

Designation | Name | Quantity, pieces |

KM-9 | Cutter | 1 |

Packaging set | ||

КМ-9.40.000 | Packaging set | 1 |

Documentation |

| |

КМ-9 РЭ | Manual | 1 |

The device and operation of the cutter

The cutter consists of a stainless steel housing 1, a drive 2, a bowl 3, a knife assembly 4, a lid 5 and a power cable 7. The product is loaded into a bowl made of stainless steel. The lid is blocked by means of a locking device 6, with microswitches installed in the housing 1.

1 - Housing; 2 - Drive; 3 - Bowl; 4 – Knife assembly; 5 - Lid;

6 – Locking device; 7 - Power cable; 8 - Speed controller.

Open the lid, install the cutting tool. Load the product into the bowl, close the lid, turn the locking device lever clockwise. Connect the machine to the electrical supply network, press the “Start” button. During operation, you can add ingredients through the hole in the lid. After processing the product, press the “Stop” button.

When loading products into the container, pay attention to two knives.

If necessary, before loading, cut the product into small pieces.

Attention! The loaded product should not fill the container more than half.

The working cycle of the cutter should not exceed 3 minutes. Long-term operation of the cutter at low speeds is unacceptable.

Transportation

The cutter must be transported from the place of receipt to the place of installation and assembly in the manufacturer's packaging. After unpacking the cutter, it is necessary to check the completeness of the delivery in accordance with clause 1.3 of the Operation Manual.

Mounting

The installation site of the machine must guarantee the safety and ensure the convenience of operation during its operation and maintenance, and must also comply with fire safety and safety regulations, requirements. It should exclude its sliding, overturning, turning over in any mode of operation.

All work on connecting the cutter to the electrical supply network and putting it into operation must be performed by a representative of a specialized service organization, in accordance with the current in the Republic of Belarus: “Electrical Installation Rules”, TKП 181-2009 “Rules for the technical operation of electrical installations of consumers”, “Intersectoral rules for labor protection”, or in accordance with similar applicable regulatory documents of the importing country.

Warranty

Warranty period - 24 months from the date of putting the machine into operation, but no later than 6 months from the date of purchase of the machine.

During the warranty period, the manufacturer eliminates failures and malfunctions in the operation of the equipment only on condition:

- Compliance with all requirements of the “Operation Manual” of the machine.

- Installation and commissioning was carried out by the specialists of the service center, or by specialists of another organization with the written permission of the manufacturer.

- Transfer (sending) to the manufacturer a copy of the completed “Equipment Commissioning Certificate” issued in full within 10 days from the date the machine was put into operation to put the equipment on warranty records.

- Carrying out monthly maintenance according to the “Operation Manual”.

- Transfer (shipping) to the manufacturer of the completed “Reclamation Act” in full.

Monthly maintenance works, in accordance with the requirements of the Operation Manual, are not warranty works and are carried out at the expense of the consumer by specialized organizations under a preliminary agreement between them.

If at least one of the above points is violated, the manufacturer disclaims warranty obligations.

Note: the issued “Equipment Commissioning Certificate” and “Reclamation Certificate” must be certified by the seal of the consumer and the enterprise that commissions or repairs and maintains.